信頼される

4つの強み

-

体制

一貫生産

モデル設計から規格検査、機械加工完成までトータルでおまかせください。その他、試作品の製作などもご相談ください。

-

技術力

マイスター

国内唯一の鋳造マイスターと鋳造テヒニカ、両方の資格を取得した技術者、各部署に有資格者が在籍しています。

-

設備

最新機器

お客様の様々なご要望に対応できるよう、最新の検査設備を導入、品質向上と改善を行っています。

-

連携

協力企業

協力企業様との連携によりお客様の様々なニーズに幅広くお応えできる体制を整えています。

型の設計から

製造、加工、検査まで

チームワークで

つくりあげる鋳物

おもな実績

-

繊維機械業界

丸編み機械部品

合繊紡糸機械部品 他 -

射出成形機業界

プラスチック射出成形機部品

ダイキャストマシン部品 他 -

産業機械業界

ガスタービン発電機部品

印刷機械部品

浚渫機械部品 他 -

船舶業界

船尾用軸部品

船舶用大型クレーン部品

船体用バルブ部品 他 -

工作機械業界

NC複合旋盤部品 他

-

鋳物への熱い思いはこちら

材質・サイズ・保管について

-

取り扱う材質鋳鉄

FC鋳鉄:FC200~350

FCD鋳鉄:FCD450~600摩耗性や切削性、機械的強度にすぐれた鋳鉄を用途に合わせて選定。

-

模型の保管

鋳造用模型の情報管理を含め、天候に左右されない専用型保管庫にて管理当社基準に基づき、お客様の鋳造用模型を大切に保管させて頂いております。詳しい内容については当社までお問い合わせください。

-

得意とするサイズ中物鋳物

取り扱いサイズ:

金枠サイズ□900~2200

1個辺りの重量50㎏~2.5t

得意なサイズ:

金枠サイズ□900~1500

1個辺りの重量100㎏~1tトミナガは「小物~中物鋳物」「小ロット多品種」を得意としています。

サイズや形状により協力会社様での対応になる可能性があります。詳しい内容については当社までお問い合わせください。

技術をもつ

有資格者の存在

-

鋳造部

(2024年06月現在)鋳造マイスター(ドイツ) 1名 鋳造テヒニカ(ドイツ) 1名 鋳造技士(日本鋳造協会認定) 4名 鋳鉄鋳物鋳造1級技能士 15名 鋳鉄鋳物鋳造2級技能士 7名 機工部

(2024年06月現在)マシニングセンター1級技能士 6名 マシニングセンター2級技能士 3名 品質保証部

(2025年1月現在)UT(超音波探傷検査)技術者レベル2 3名 PT(浸透探傷検査)技術者レベル2 3名 -

国内で唯一、ドイツの国家資格である「鋳造マイスター」「鋳造テヒニカ」の両資格を取得しています。船舶や産業機械に欠かせない鋳鉄品製造の基盤を支える一人。

専務取締役

梅原 利一

高品質を保つための

最新機器

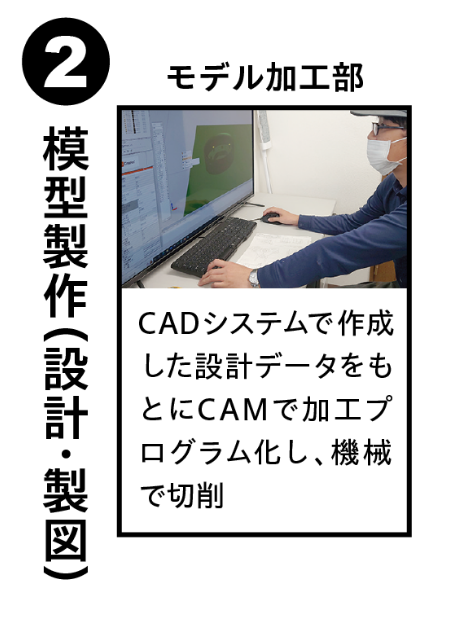

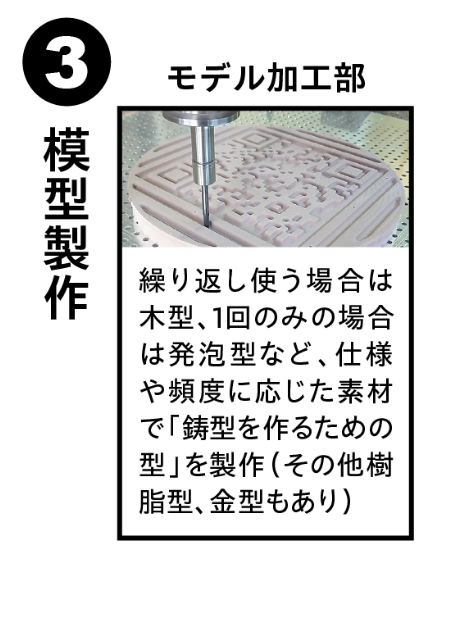

モデル加工部

型のモデル設計は鋳物づくりにおいての礎となる重要な工程です。CAD/CAMを使用し、鋳造から機械加工までの全工程を考慮した型製作を行っております。

加工能力

| 対応材質 | 対応サイズ | 対応拡張子 |

|---|---|---|

| ケミカルウッド | 2200×1700(機械加工) | IGES、STL、STEP、ACIS |

設備内容

| 設備機械 | 型式・規格 | メーカー | 台数 |

|---|---|---|---|

| MC57-1 | “テーブル2000×1500mm 高さ3700mm仕様”) |

キクカワエンタープライズ | 1台 |

| 3DCAD/CAMシステム | PC2台(CADとCAM) | Cimatron | 1台 |

| 糸鋸 | 旭精機 | 1台 | |

| 手押しカンナ盤 | EJ302 | 飯田 | 1台 |

| 帯鋸 | BS750 | リョービ | 1台 |

| ユニバーサルサンダー | 長谷川 | 1台 | |

| 横切盤 | 東海 | 1台 | |

| 自動一面カンナ | SP202 | 飯田 | 1式 |

| サイレンサー付き集塵機 | 鈴木 | 1式 |

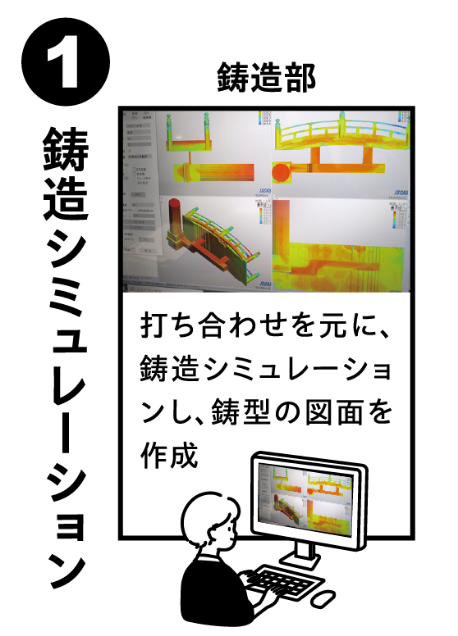

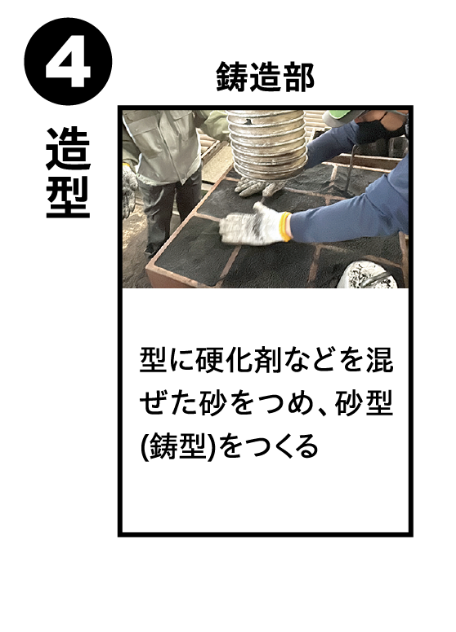

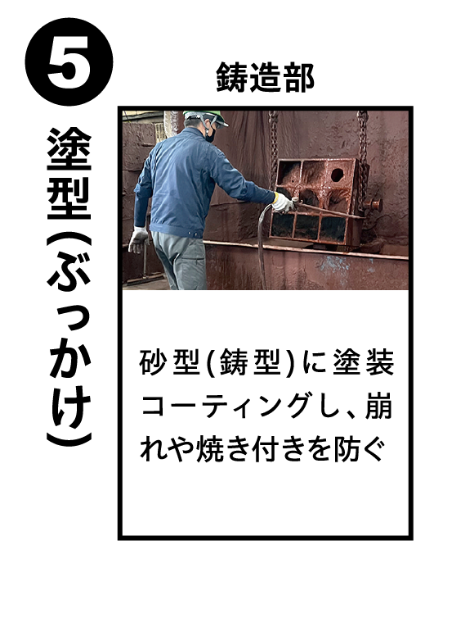

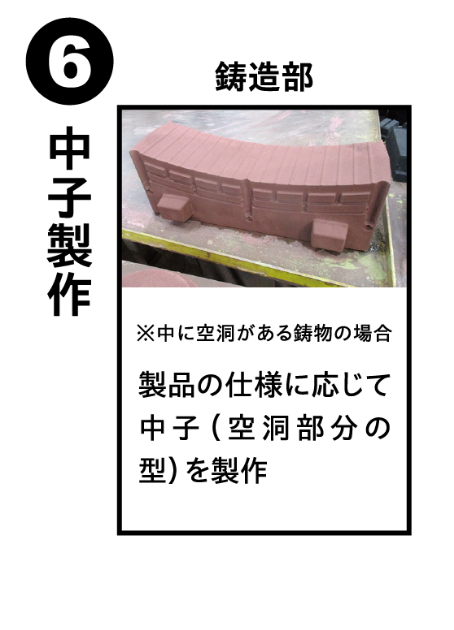

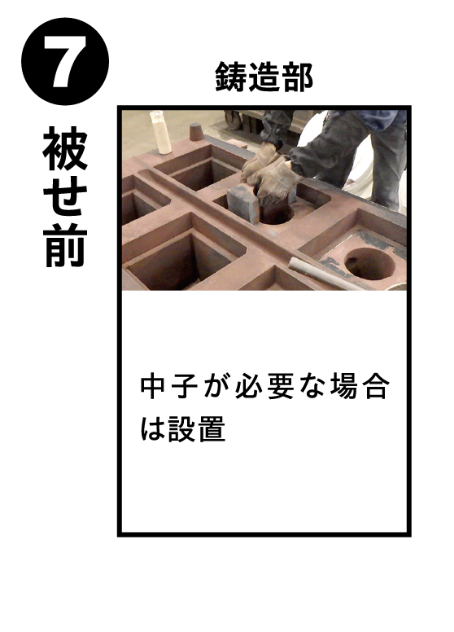

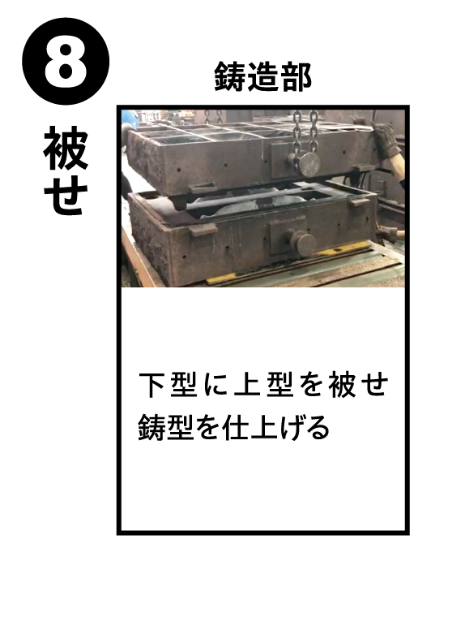

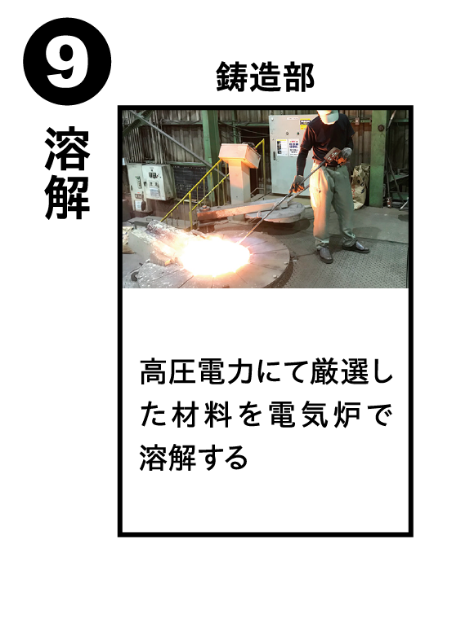

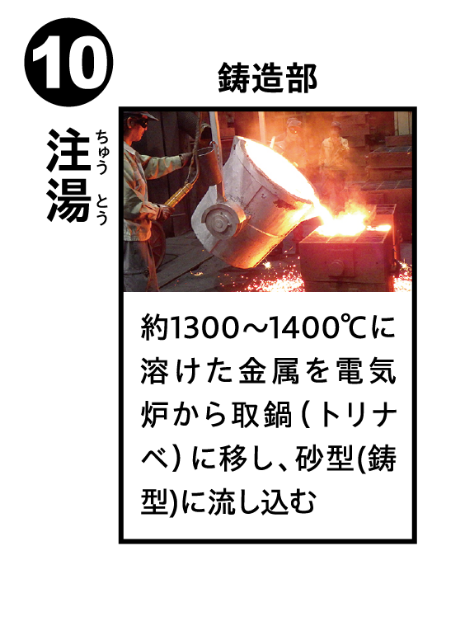

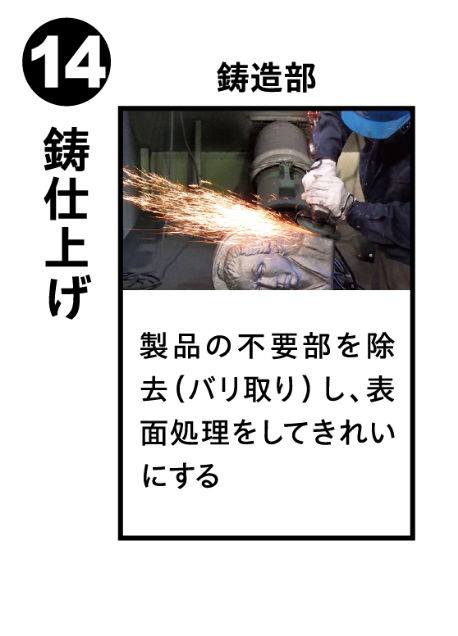

鋳造部

日々進化する鋳造技術を取り入れながら積み重ねてきた技術を受け継ぎ安定した鋳物を提供いたします。

鋳造能力

| 溶解能力 | 生産能力 | 対応材質 |

|---|---|---|

| MAX 500t/月 | 400t | ねずみ鋳鉄(FC200〜350) ダクタイル鋳鉄(FCD450〜600) |

| FC:FCD比率 | 最小〜最大 | 最大枠サイズ |

| FC60%:FCD40% | 鋳込み重量 50kg~2.5t | 2200mm×2200mm |

設備内容

| 設備機械 | 型式・規格 | メーカー | 台数 |

|---|---|---|---|

| ニューフラン自硬性砂再生機 | 5t/h SCMB-30H | 太洋マシナリー | 1台 |

| ロングアームミキサー | LAM-10SS 12t/h | 太洋マシナリー | 1台 |

| フラン砂処理ミキサー | 5t,3t | 新東工業 | 1台 |

| 高周波誘導炉 | 1.5t,750kw,IGBT方式2電源 | 富士電機 | 2炉 |

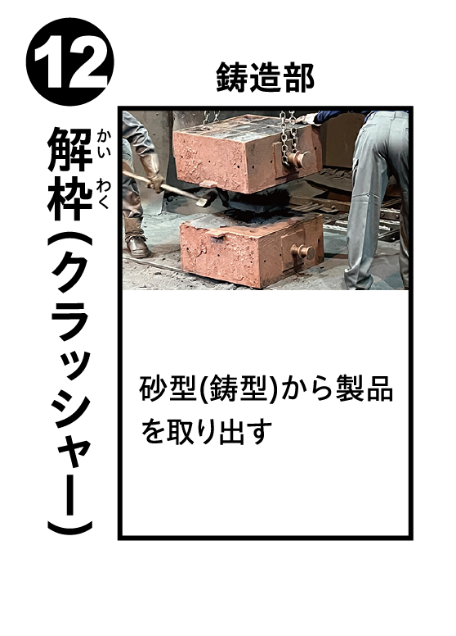

| アンダーパンチクラッシャー | UP-2,10t/h | 清田鋳機 | 1台 |

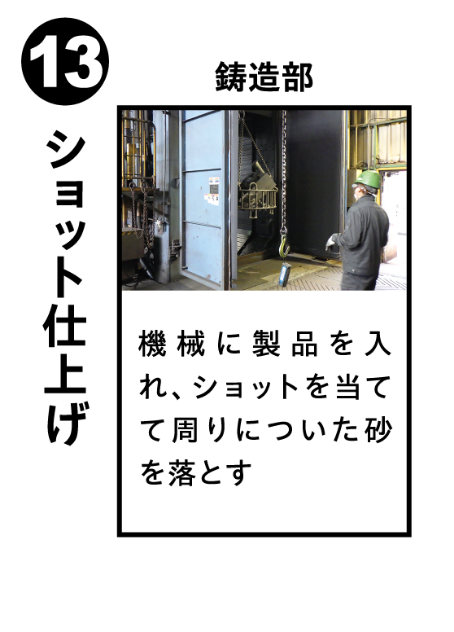

| モノレールブラスト | KSB-25 ハンガー式 | 新東工業 | 1台 |

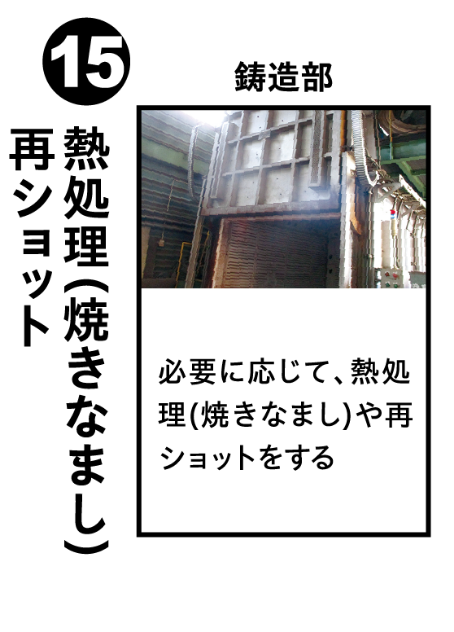

| 台車式電熱処理炉 | W2000×H1450×L3000 | 水上電機製作所 | 1式 |

| 天井クレーン | 2.8t | 5基 | |

| 自走式トラバーサー | STA-1600 | サン工業 | 1基 |

| 自走式トラバーサー | STA-3000 | サン工業 | 2基 |

| 自走式ローラーコンベアー | SRAP-1500 | サン工業 | 4基 |

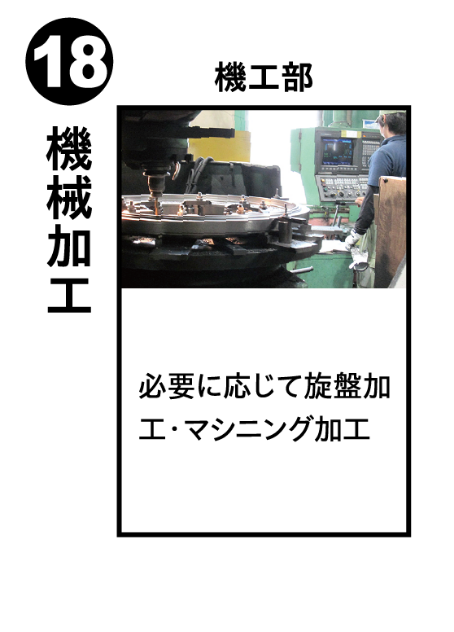

機工部

最速かつ高精度な加工技術により確かな製品をお届けします。様々なニーズにお応えできるよう常に挑戦し続けます。

加工能力

| 旋盤加工 | マシニング | 加工精度 |

|---|---|---|

| Φ2000mm | 3700mm×2000mm×600mm | 50μ〜 |

| 材質 | ||

| 鋳鉄100% |

設備内容

- 旋盤加工

- マシニング

- その他設備

| 設備機械 | 型式・規格 | メーカー | 台数 |

|---|---|---|---|

| CNC立旋盤 | TM216M,2100ф×1600H,ATC-12 | OM製作所 | 1台 |

| CNC立旋盤 | NEO16,2000ф×1600H,ATC-12 | OM製作所 | 1台 |

| CNC旋盤 | LH55N,1100ф×2000H | オークマ | 1台 |

| CNC立旋盤 | NEOa16ex,2100ф×1600H | OM製作所 | 1台 |

| ターニングセンターCNC旋盤 | TUE-150(S) Ф1600 ATC-18 | 東芝機械 | 1台 |

| NC正面旋盤 | FNC-LHS-3616 1600 | 西部工機 | 1台 |

| NC正面旋盤 | FNC-2712MIC 1000 | 西部ハイテック | 1台 |

| NC正面旋盤 | FNC-2716MIC 1000 | 西部ハイテック | 1台 |

| 汎用正面旋盤 | LHC-2712 ф1000 | 西部工機 | 1台 |

| 正面旋盤 | LHS-2716 1600 | 西部ハイテック | 1台 |

| 正面旋盤 | LHS-2712 Ф1250 | 西部ハイテック | 1台 |

| NC正面旋盤 | LHS-2712 1000 | 西部ハイテック | 1台 |

| 立型主軸NC | V100R, 1250ф,V-12 | オークマ | 1台 |

| 設備機械 | 型式・規格 | メーカー | 台数 |

|---|---|---|---|

| 立型MC | MC-60VA | オークマ | 1台 |

| 5面門型MC | MCV-B,ATC-50,20x30A | オークマ | 1台 |

| 5面門型MC | MCV-B,ATC-70,25x45 | オークマ | 1台 |

| 立型MC | MC-5VA,ATC-20 | オークマ | 1台 |

| 立型MC | MILLAC761V,1800x720,ATC36 | オークマ | 1台 |

| 立型MC | MILLAC611V,610x1300,ATC30 | オークマ | 1台 |

| 立型MC | MILLAC561V,ATC30 | 大隈豊和 | 1台 |

| 横型MC | A99e,2PA,ATC-132 | 牧野フライス製作所 | 1台 |

| 横型MC | HM800,6PA,ATC-120 | OKK | 1台 |

| 横型MC | HM1000S,2PA,ATC-120 | OKK | 1台 |

| 横中ぐり盤 | BTD110R-16,1400x1600,ATC90 | 東芝機械 | 1台 |

| 設備機械 | 型式・規格 | メーカー | 台数 |

|---|---|---|---|

| ラジアルボール盤 | BR-15 | 大鳥機工 | 1台 |

| ラジアルボール盤 | RH-1300 | 富永鉄工 | 1台 |

| ラジアルボール盤 | YR5-130 | 吉田鉄工所 | 1台 |

| 立旋盤 | VTO-12,1000 | OM製作所 | 1台 |

| 天井クレーン | 5t | 2基 |

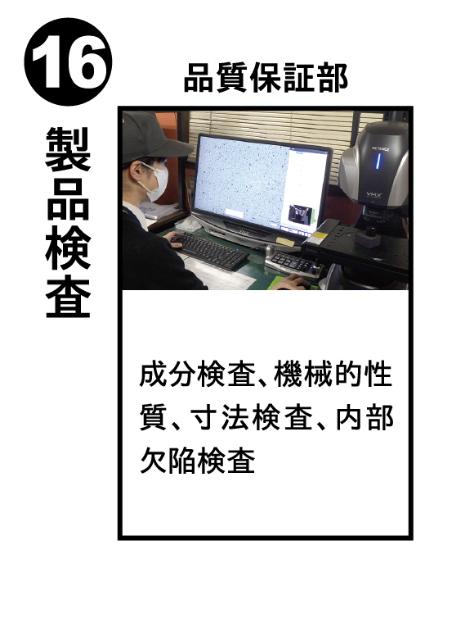

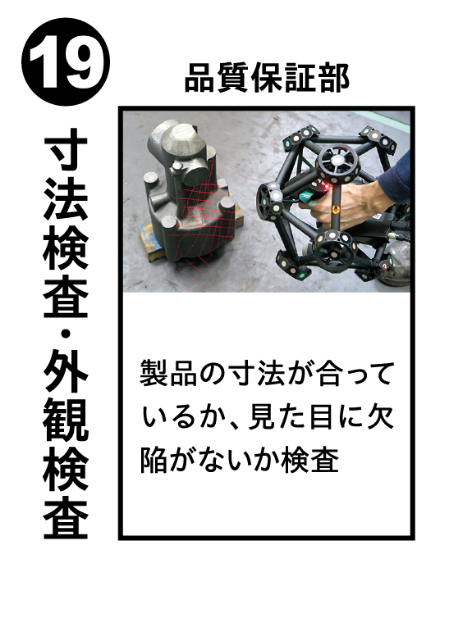

品質保証部

最新の測定技術を用いた様々な品質検査を行い、お客様からの信頼とご要望に確かな技術でお応えする体制を整えております。

検査能力

| 超音波探傷検査(UT) | 浸透探傷検査(PT) | 成分分析による 材質管理 |

鋳造シミュレーション による湯流れ解析、 内部欠陥箇所の予測 |

| 3Dスキャナーによる 寸法形状検査 |

デジタル マイクロスコープによる 組織検査 |

設備内容

| 設備機械 | 型式・規格 | メーカー | 台数 |

|---|---|---|---|

| 発光分光分析装置 | GS1000-Ⅱ | OBLF | 1台 |

| 万能試験機 | UMH-30 | 島津製作所 | 1台 |

| ブリネル硬度計 | 3000 | 島津製作所 | 1台 |

| 鋳造シミュレーション | JS-CAST | クオリカ | 1台 |

| QCレコーダー 溶湯管理機 | NSP-3603 | ニッサブ | 1台 |

| 3次元CAD | KEY CREATOR | KUBOTEC | 1台 |

| 携帯用ブリネル硬度計 | T-UD3 Lad | NOVOTEST | 1台 |

| 携帯型超音波探傷器 | USM35X | Krautkramer | 1台 |

| 三次元測定機 X900,Y1600,Z600 | CRYSTA-APEX S9166 接触タイプ |

ミツトヨ | 1台 |

| 3Dスキャナー | MetraSCAN 3D 非接触カメラタイプ |

クレアフォームジャパン | 1台 |

| デジタルマイクロスコープVHX-7000 | VHX-7000 4KCMOS | KEYENCE | 1台 |

| 自動埋込機 | シンプリメット4000 | ビューラー | 1台 |

| 自動研磨機 | エコメット30 | ビューラー | 1台 |

| 試料切断機 | FTC-255AS | フューチャーテック | 1台 |

| ワイドエリア三次元測定機 | WM-C6210 | KEYENCE | 1台 |

| 試料自動研磨装置 | SB1型 | エステック | 1台 |

生産工程を簡略化し、効率的で安定した品質の製品をユーザーに提供します。

また、鋳造の魅力を分かり易く若い世代に伝えていき、匠に認定される人材を育てていきたいです。